Adres

16100, 5.cd No: 13

Hasanağa Organize Sanayi Bölgesi, Nilüfer/Bursa

Çalışma Saatleri

Haftaiçi: 09:00 - 18:00

|

Service Pressure (kgf/cm²) |

HWS-040AL |

HWS-048AL |

HWS-055AL |

HWS-065AL |

HWS-075AL |

HWS-090AL |

|---|---|---|---|---|---|---|

|

Service Pressure (kgf/cm²) |

20 ~ 70 |

20 ~ 70 |

20 ~ 70 |

20 ~ 70 |

20 ~ 70 |

20 ~ 70 |

|

Stroke (mm) |

8 |

10 |

12 |

14 |

16 |

20 |

|

Piston Diameter (mm) |

Φ15 |

Φ16 |

Φ20 |

Φ22 |

Φ25 |

Φ30 |

|

Support Force (kgf) / Operating Pressure (kgf/cm²) |

320 / 70 |

480 / 70 |

900 / 70 |

1800 / 70 |

2300 / 70 |

3000 / 70 |

|

Operation Type |

Single Acting |

Single Acting |

Single Acting |

Single Acting |

Single Acting |

Single Acting |

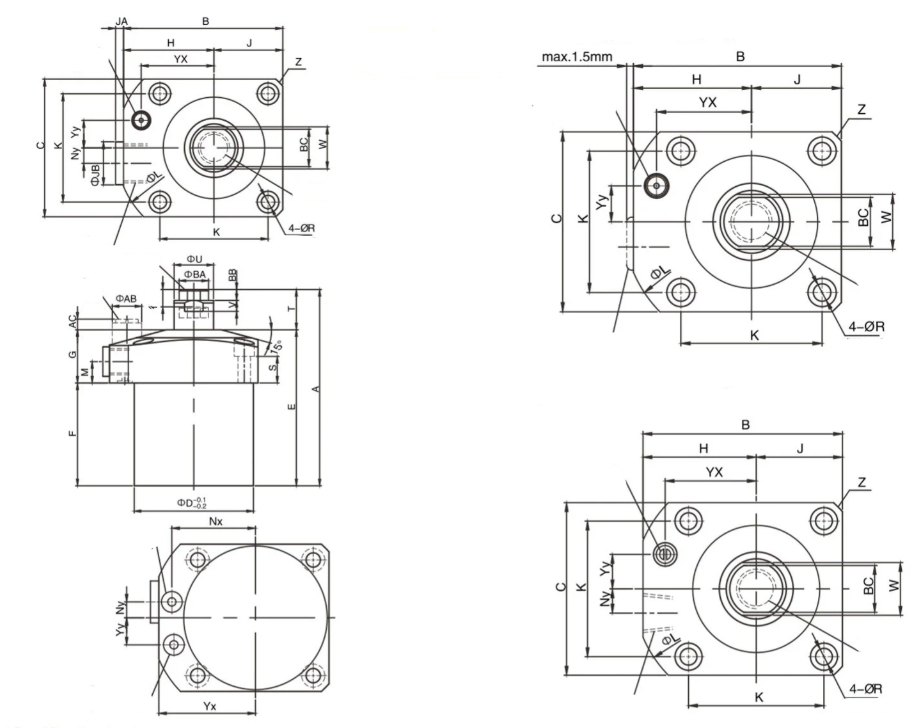

| Dimension | HWS-040AL | HWS-048AL | HWS-055AL | HWS-065AL | HWS-075AL | HWS-090AL | ||

|---|---|---|---|---|---|---|---|---|

| A | 75 | 85 | 97 | 115 | 142 | 169 | ||

| B | 54 | 61 | 69 | 81 | 92 | 107 | ||

| C | 45 | 51 | 60 | 70 | 80 | 95 | ||

| D | 40 | 48 | 55 | 65 | 75 | 90 | ||

| E | 56 | 64 | 70 | 85 | 107 | 128 | ||

| F | 31 | 39 | 45 | 56 | 72 | 88 | ||

| G | 25 | 25 | 25 | 29 | 35 | 40 | ||

| H | 31.5 | 35.5 | 39 | 46 | 52 | 59.5 | ||

| J | 22.5 | 25.5 | 30 | 35 | 40 | 47.5 | ||

| K | 34 | 40 | 47 | 55 | 63 | 75 | ||

| L | 68 | 73 | 80 | 94 | 106 | 126 | ||

| M | 11 | 11 | 11 | 11 | 13 | 13 | ||

| Nx | 26 | 30 | 33.5 | 39.5 | 45 | 52.5 | ||

| Ny | 5 | 0 | 0 | 0 | 0 | 0 | ||

| P | 3 | 3 | 3 | 5 | 5 | 5 | ||

| Q | 9.5 | 9.5 | 11 | 11 | 14 | 17.5 | ||

| R | 5.5 | 5.5 | 6.8 | 6.8 | 9 | 11 | ||

| S | 14.5 | 13.5 | 11.5 | 14.5 | 17 | 18 | ||

| T | 19 | 21 | 27 | 30 | 35 | 41 | ||

| U | 15 | 16 | 20 | 22 | 25 | 30 | ||

| V | 6 | 6 | 8 | 9 | 9 | 10.5 | ||

| W | 13 | 13 | 17 | 19 | 22 | 24 | ||

| X (Diameter x Depth) | M10x11 | M10x11 | M12x13 | M12x13 | M12x20 | M12x20 | ||

| Yx | 25 | 28 | 31 | 37 | 42.5 | 50 | ||

| Yy | 8 | 11 | 13 | 14 | 15 | 15 | ||

| Z | c1 | C3 | R40 | R47 | R53 | R63 | ||

| AB | 12 | 12 | 12 | 12 | 12 | 12 | ||

| AC | 5 | 4 | 3.5 | 2 | 1.5 | 0 | ||

| BA | 12.5 | 12.5 | 16.5 | 16.5 | 21.5 | 21.5 | ||

| BB | 4 | 4 | 6 | 6 | 9 | 9 | ||

| BC | 11 | 11 | 14 | 14 | 19 | 19 | ||

| CA | M5x0.8 | M5x0.8 | M6 | M6 | M8 | M10 | ||

| JA | 3.5 | 3.5 | 3.5 | 3.5 | 4.5 | 4.5 | ||

| JB | 14 | 14 | 14 | 14 | 19 | 19 | ||

| Stroke | 8 | 10 | 12 | 14 | 16 | 20 | ||

| Hydraulic Inlet | -C Type | G1/8 | G1/8 | G1/8 | G1/8 | G1/4 | G1/4 | |

| -S Type | Rc1/8 | Rc1/8 | Rc1/8 | Rc1/8 | Rc1/4 | Rc1/4 | ||

| Sealing Plug (R Type) | -G Type | Rc1/8 | Rc1/8 | Rc1/8 | Rc1/8 | Rc1/4 | Rc1/4 | |

| O-Ring Seal (-C/-G Type) | P5 / P5 / P5 / P7 / P7 / P7 | |||||||

| Air Vent | Rc1/8 | |||||||