Adres

16100, 5.cd No: 13

Hasanağa Organize Sanayi Bölgesi, Nilüfer/Bursa

Çalışma Saatleri

Haftaiçi: 09:00 - 18:00

|

Specification |

Value |

|---|---|

|

Operating Pressure |

2–7 MPa |

|

Maximum Support Force |

For 30 mm diameter: 4900 N (approx. 500 kgf) |

|

Contact Force with Workpiece |

0.3–0.8 kgf (low) |

|

Operating Temperature |

0 °C ~ 70 °C |

|

Compatible Hydraulic Oil |

ISO VG 32 or equivalent |

|

Installation Orientation |

Vertical (piston rod facing up), can also be used horizontally |

| Model | HWS-26AL-S | HWS-26BL-S | HWS-30AL-S | HWS-30BL-S | HWS-36AL-S | HWS-36BL-S | HWS-45AL-S | HWS-45BL-S |

|---|---|---|---|---|---|---|---|---|

| Operating Pressure Range (kgf/cm²) | 20 ~ 70 | |||||||

| Stroke (mm) | 5.5 | 5.5 | 8 | 8 | 10 | 10 | 10 | 10 |

| Piston Rod Diameter (mm) | Φ10 | Φ10 | Φ12 | Φ12 | Φ15 | Φ15 | Φ16 | Φ16 |

| Support Force (kgf)/Operating Pressure (kgf/cm²) | 170/50 | 170/50 | 220/50 | 220/50 | 330/50 | 330/50 | 530/50 | 530/50 |

| Operation Type | Single Acting | |||||||

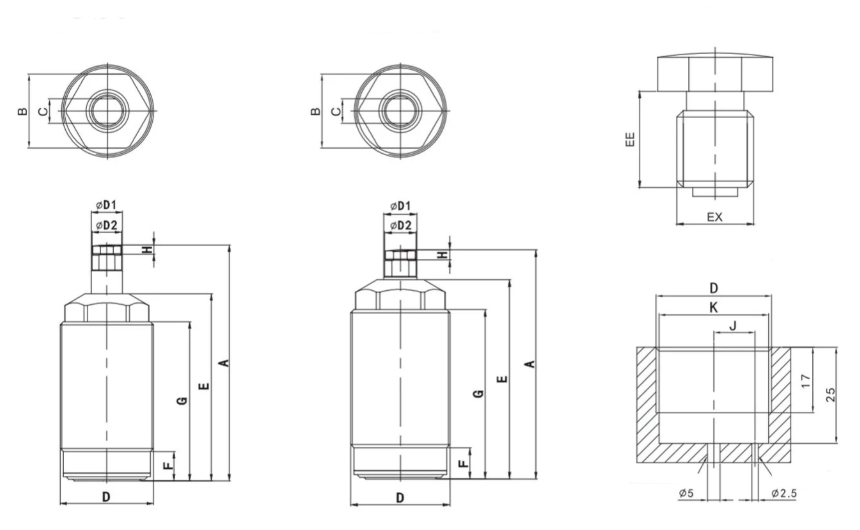

| Model | HWS-26AL-S | HWS-26BL-S | HWS-30AL-S | HWS-30BL-S | HWS-36AL-S | HWS-36BL-S | HWS-45AL-S | HWS-45BL-S |

|---|---|---|---|---|---|---|---|---|

| A | 72.5 | 66 | 81.7 | 73.7 | 77 | 69 | 92 | 82 |

| B | 22 | 22 | 24 | 24 | 30 | 30 | 36 | 36 |

| C | 9 | 9 | 10 | 10 | 11 | 11 | 14 | 14 |

| D | M26x1.5 | M26x1.5 | M30x1.5 | M30x1.5 | M36x1.5 | M36x1.5 | M45x1.5 | M45x1.5 |

| E | 57 | 57 | 62 | 62 | 58 | 58 | 71 | 71 |

| F | 8.5 | 8.5 | 9.5 | 9.5 | 10 | 10 | 9.5 | 9.5 |

| G | 49 | 49 | 54 | 54 | 48 | 48 | 60 | 60 |

| H | 3.5 | 3.5 | 4.5 | 4.5 | 4 | 4 | 4 | 4 |

| J | 9 | 9 | 11 | 11 | 13 | 13 | 16 | 16 |

| K | 24.5 | 24.5 | 28.5 | 28.5 | 34.5 | 34.5 | 43.5 | 43.5 |

| D1 | 10 | 10 | 12 | 12 | 15 | 15 | 16 | 16 |

| D2 | 9.5 | 9.5 | 11.5 | 11.5 | 12.5 | 12.5 | 15.5 | 15.5 |

| EE | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| EX | M8 | M8 | M8 | M8 | M10 | M10 | M10 | M10 |